PRODUCTS

Complete Equipment for CVD vapor deposition coating

You are here:Home > Products >

Complete Equipment for CVD vapor deposition coating

SILICON CARBON NEGATIVE ELECTRODE FLUIDIZED BED

Features Description :

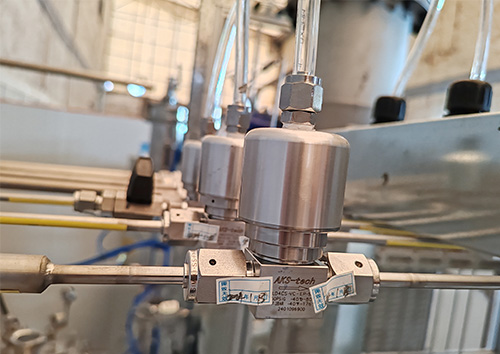

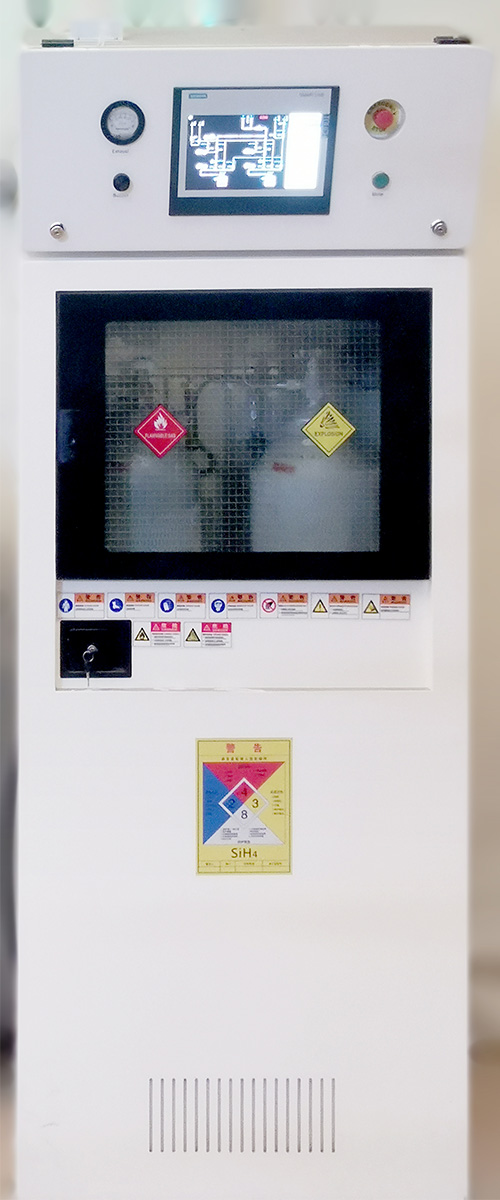

Silicon carbon negative electrode fluidized bed is a production device that uses CVD vapor deposition and coating of silicon carbon negative electrode materials. Using carrier gas to fluidize porous carbon powder in a reaction vessel through a gas distributor, and then mixing the silicon containing gas raw materials through a flow rate ratio before entering the reaction vessel; At high temperatures of 500-750℃, silicon containing gas raw materials are cracked into silicon and hydrogen, and silicon atoms deposit in porous carbon pores to form nano silicon. After sedimentation is completed, acetylene is introduced again for high-temperature cracking to complete carbon coating treatment.

Silicon carbon negative electrode fluidized bed is a production device that uses CVD vapor deposition and coating of silicon carbon negative electrode materials. Using carrier gas to fluidize porous carbon powder in a reaction vessel through a gas distributor, and then mixing the silicon containing gas raw materials through a flow rate ratio before entering the reaction vessel; At high temperatures of 500-750℃, silicon containing gas raw materials are cracked into silicon and hydrogen, and silicon atoms deposit in porous carbon pores to form nano silicon. After sedimentation is completed, acetylene is introduced again for high-temperature cracking to complete carbon coating treatment.

Chinese

Chinese English

English

粤公网安备 44060402001578号

粤公网安备 44060402001578号